Automotive Parts Magnesium Die Casting Market Trends and Forecast 2025-2033

0

0

Posted: Fri January 24 4:20 AM PST

Member: stanley huds

Global Automotive Parts Magnesium Die Casting Market Statistics: USD 5.5 Billion Value by 2033

Summary:

- The global automotive parts magnesium die casting market size reached USD 3.3 Billion in 2024.

- The market is expected to reach USD 5.5 Billion by 2033, exhibiting a growth rate (CAGR) of 5.51% during 2025-2033.

- Asia Pacific leads the market, accounting for the largest automotive parts magnesium die casting market share.

- Pressure die casting represents the largest segment as it is a highly efficient process that allows for the rapid production of complex metal parts in large volumes.

- Body parts hold the biggest market share owing to the rising focus on developing various light weight and functional parts.

- In response to stringent fuel efficiency and emission standards, the automotive industry is prioritizing light weighting strategies.

- Magnesium die casting offers unparalleled design flexibility, enabling the production of complex geometries and intricate shapes with high precision.

Industry Trends and Drivers:

- Light weighting Initiatives:

To meet strict fuel efficiency and emission standards, the automotive industry is focusing on making vehicles lighter. Magnesium die casting is key to this effort because it is exceptionally lightweight. By using magnesium parts in their designs, automakers can cut down on overall weight while maintaining strength and performance. This reduction leads to better fuel efficiency and lower greenhouse gas emissions, which is essential for meeting environmental regulations and consumer demand for greener cars. As the industry moves towards electric and hybrid vehicles, reducing weight becomes even more critical. It helps extend battery range and improves overall vehicle efficiency.

-

Design Flexibility and Cost Efficiency:

Magnesium die casting allows for great design flexibility. It enables the creation of complex shapes with high precision. This versatility helps automotive manufacturers optimize parts for better performance. The process is also cost-efficient, making it a viable option for mass production. Automakers can streamline workflows, reduce lead times, and lower overall costs. They can create lightweight, durable parts with intricate designs at a competitive price. This offers a significant advantage in the automotive market.

-

Material Innovation and Advancements:

Ongoing research in material science is boosting magnesium die casting technology. Innovations in alloy formulations and manufacturing techniques are expanding its applications in automotive components. New alloys enhance strength, corrosion resistance, and castability. This advancement opens doors for use in critical systems like powertrains, chassis, and structural components. Moreover, process automation and quality control improvements are making production more efficient. They ensure consistent part quality, which builds confidence in magnesium die casting among automotive manufacturers.

Request for a sample copy of this report: https://www.imarcgroup.com/automotive-parts-magnesium-die-casting-market/requestsample

Automotive Parts Magnesium Die Casting Market Report Segmentation:

By Production Process:

- Pressure Die Casting

- Vacuum Die Casting

- Gravity Die Casting

- Squeeze Die Casting

Pressure die casting represents the largest segment as it is a highly efficient process that allows for the rapid production of complex metal parts in large volumes.

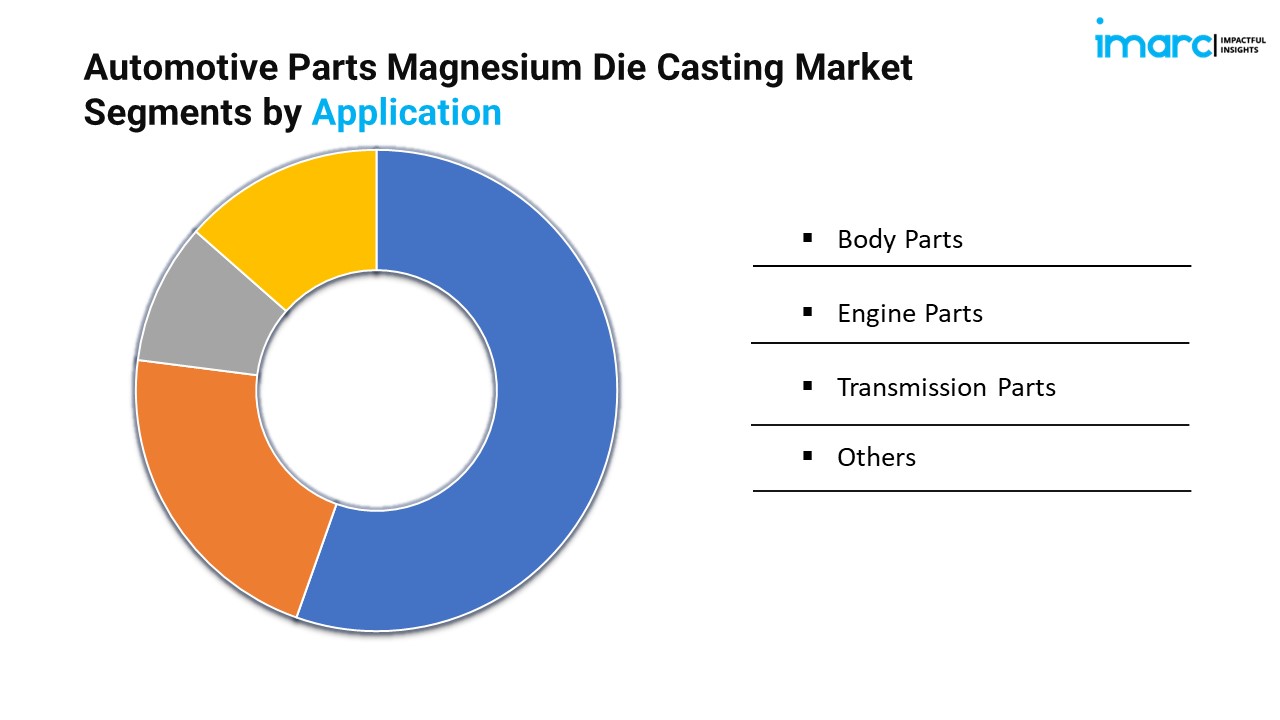

By Application:

- Body Parts

- Engine Parts

- Transmission Parts

- Others

Body parts hold the biggest market share owing to the rising focus on developing various light weight and functional parts.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific’s dominance in the automotive parts magnesium die casting market is attributed to investment in research operations, leading to the development of advanced technological improvements in this field.

Top Automotive Parts Magnesium Die Casting Market Leaders:

The automotive parts magnesium die casting market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Chicago White Metal Casting Inc.

- Dynacast International Inc. (Form Technologies Company)

- Georg Fischer Ltd.

- Gibbs Die Casting Corporation (Koch Enterprises Inc.)

- Meridian Lightweight Technologies

- Morimura Bros. Inc.

- Ortal Diecasting Ltd.

- Pace Industries (Leggett & Platt Incorporated)

- Ryobi Limited

- Sandhar Technologies Limited

- Shiloh Industries Inc.

- Twin City Die Castings Co.

Note: If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Comments

Please login above to comment.