Aerospace Materials Market Size, Share, Growth, and Trends Forecast 2024-2032

0

0

Posted: Mon November 04 4:28 AM PST

Member: stanley huds

Global Aerospace Materials Market Statistics: USD 36.3 Billion Value by 2032

- The global aerospace materials market size reached USD 25.0 Billion in 2023.

- The market is expected to reach USD 36.3 Billion by 2032, exhibiting a growth rate (CAGR) of 4.15% during 2024-2032.

- North America displays clear dominance in the market, accounting for the largest share in the aerospace materials market.

- Aluminum alloys represent the largest class because they are lightweight and have a high strength-to-weight ratio.

- Commercial aircraft account for the largest share of the market owing to the growing number of passengers traveling by air.

- The rising demand for aircraft due to increasing air travel among individuals for various purposes is fueling the growth of the market.

- Innovations such as carbon fibre composites, titanium alloys and high performance polymers offer significant advantages over traditional materials.

Request for a sample copy of this report: https://www.imarcgroup.com/aerospace-materials-market/requestsample

Industry Trends and Drivers:

- Increasing Demand for Aircraft:

The growing demand for aircraft due to increasing air travel among individuals for various purposes is strengthening the market growth. As a result, airlines are expanding their fleets to accommodate more passengers and routes. Additionally, older aircraft are being replaced with newer and more fuel-efficient models, boosting the demand for aerospace materials. This trend is not just limited to commercial aviation but also extends to military applications, where modernization of air forces and incorporation of advanced technologies require substantial investments in new aircraft. Steady growth in both commercial and military aviation sectors ensures a steady and robust demand for aerospace materials.

- Technological Advancements:

Innovations such as carbon fiber composites, titanium alloys and high-performance polymers offer significant advantages over traditional materials. These advanced materials provide better strength-to-weight ratios, corrosion resistance and durability, which are essential for improving fuel efficiency and reducing maintenance costs. The use of composite materials in aircraft structures can lead to significant weight savings, which in turn reduces fuel consumption and reduces emissions. In addition, continued research and development (R&D) efforts in materials science are driving the adoption of these high-performance materials and ensuring that aircraft can meet the ever-increasing demands for efficiency, safety and performance.

- Focus on Fuel Efficiency and Emission Reduction:

The market growth is being fueled by an increasing focus on fuel efficiency and emission reduction due to environmental concerns and regulatory pressures. The development and use of lightweight and high-strength materials is central to these efforts. Lightweight aircraft consume less fuel and produce fewer emissions, making them more environmentally friendly and cost-effective to operate. Materials such as advanced composites and lightweight alloys enable manufacturers to design more aerodynamic and fuel-efficient aircraft. This focus is in line with global sustainability goals and regulatory requirements that aim to reduce the aviation industry's carbon footprint.

We explore the factors driving the growth of the market, including technological advancements, consumer behaviors, and regulatory changes, along with emerging aerospace materials market trends.

Aerospace Materials Market Report Segmentation:

Breakup By Type:

- Aluminium Alloys

- Titanium Alloys

- Super Alloys

- Steel Alloys

- Composite Materials

Aluminum alloys represent the largest class because they are lightweight and have a high strength-to-weight ratio.

Breakup By Aircraft Type:

- Commercial Aircraft

- Business and General Aviation

- Helicopters

Commercial aircraft account for the largest share of the market owing to the growing number of passengers traveling by air.

Breakup By Application:

- Interior

- Passenger Seating

- Galley

- Interior Panels

- Others

- Exterior

- Propulsion Systems

- Air Frame

- Tail and Fin

- Windows and Windshields

Exterior parts account for the largest market share owing to the increasing focus on maintaining structural integrity.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys a leading position in the aerospace materials market, which can be attributed to the presence of a well-established aerospace industry.

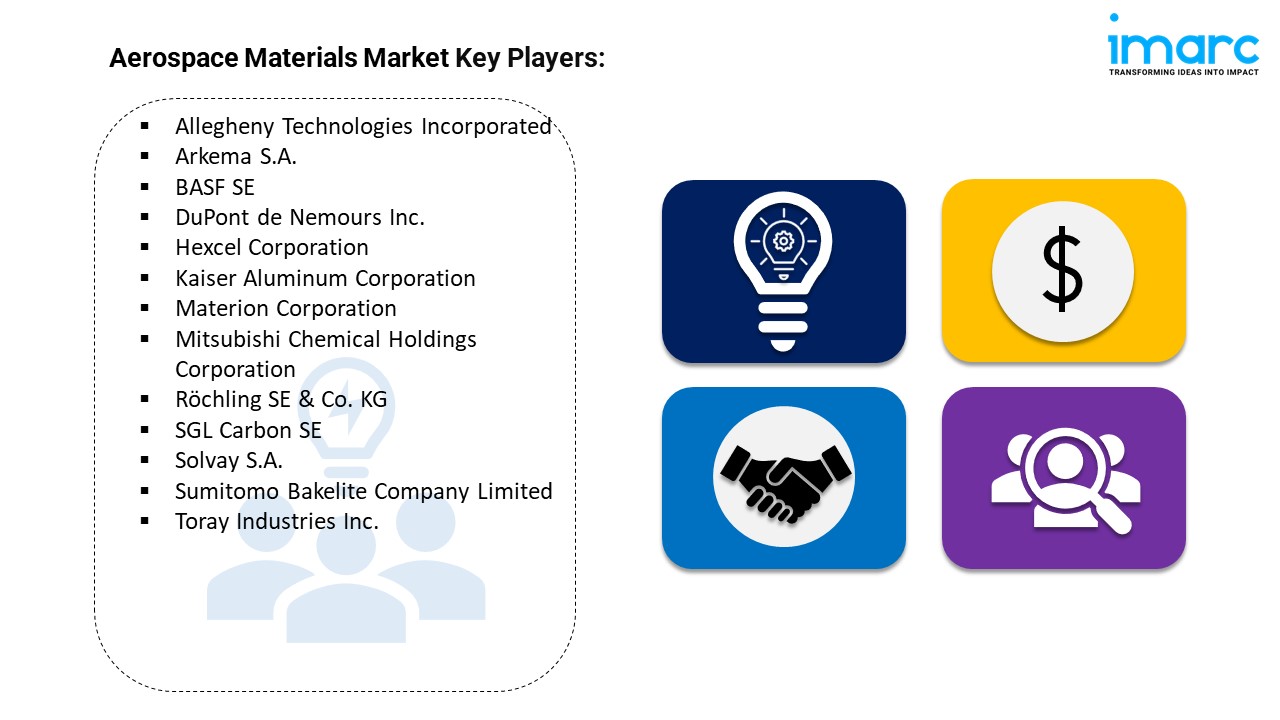

Top Aerospace Materials Market Leaders:

The aerospace materials market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Allegheny Technologies Incorporated

- Arkema S.A.

- BASF SE

- DuPont de Nemours Inc.

- Hexcel Corporation

- Kaiser Aluminum Corporation

- Materion Corporation

- Mitsubishi Chemical Holdings Corporation

- Röchling SE & Co. KG

- SGL Carbon SE

- Solvay S.A.

- Sumitomo Bakelite Company Limited

- Toray Industries Inc.

Note: If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1–631–791–1145

Comments

Please login above to comment.