Unleashing Precision: The SS-80–3NC CNC Automatic Busbar Machine Explained

0

0

Posted: Sat August 17 1:14 AM PDT

Business: My Business Name

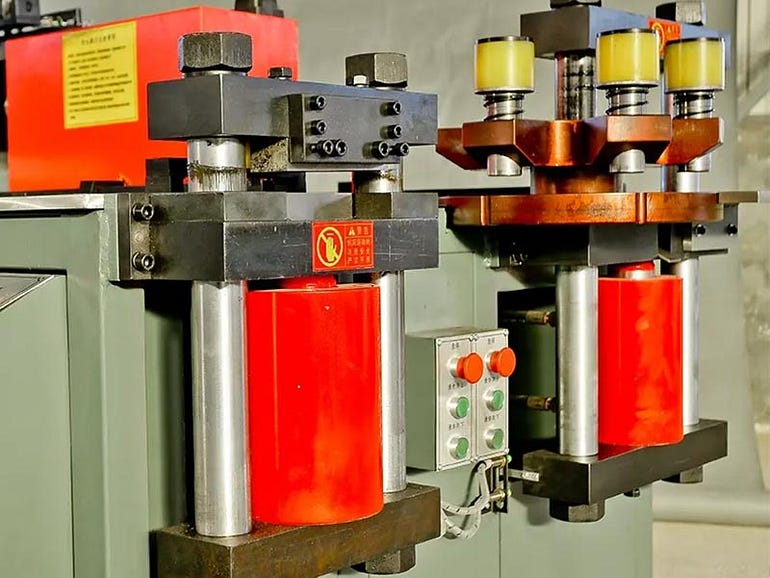

Imagine a tool that could transform raw materials into precise components with the push of a button — no fuss, no muss, just perfection every time. That’s essentially what the SS-80–3NC CNC Automatic Busbar Machine offers to the manufacturing world. As a bus bar bending cutting punching machine, this piece of equipment is not just a machine; it’s a revolution in precision and efficiency, designed to meet the high demands of modern electrical manufacturing.

Overview of the SS-80–3NC

The SS-80–3NC is a powerhouse bus bar bending cutting punching machine that integrates multiple functions into one seamless operation. This machine is the Swiss Army knife of the busbar machine world, capable of bending, cutting, and punching with incredible precision and speed.

Why Precision Matters

In the world of electrical manufacturing, precision is not just a luxury; it’s a necessity. A fraction of a millimeter can be the difference between a safe electrical system and a potential hazard. The SS-80–3NC ensures that every piece is accurate to the specifications, every time.

Key Features of the SS-80–3NC

This machine boasts features such as advanced CNC technology, multi-tool capabilities, and automated loading and unloading systems that reduce human error and increase production efficiency.

The Technology Behind the Machine

At the heart of the SS-80–3NC is its CNC (Computer Numerical Control) technology, which allows for precise digital control over the bending, cutting, and punching processes, ensuring consistent quality and repeatability.

Applications Across Industries

The versatility of the SS-80–3NC makes it suitable for a variety of industries, from electrical and telecommunications to automotive and aerospace, where precision metal components are crucial.

Enhancing Production Efficiency

By combining multiple functions into one machine, the SS-80–3NC cuts down on processing time and increases throughput, allowing businesses to meet higher demand more efficiently.

User Experience and Interface

The SS-80–3NC is designed with the operator in mind, featuring an intuitive interface that simplifies complex tasks and makes the machine accessible to users of all skill levels.

Maintenance and Longevity

Built to last, this machine requires minimal maintenance, thanks to its robust construction and quality components, ensuring long-term reliability and performance.

Cost Savings and ROI

Investing in the SS-80–3NC can lead to significant cost savings over time, reducing the need for multiple machines and decreasing labor costs through automation.

Environmental Impact

With features that reduce waste and improve energy efficiency, the SS-80–3NC is not only good for your business but also better for the planet.

Integrating with Other Systems

The SS-80–3NC can be easily integrated into existing production lines, enhancing overall workflow and connectivity between different stages of the manufacturing process.

Customer Testimonials

Hear from real users who have transformed their production capabilities and business outcomes with the help of the SS-80–3NC.

How to Get Started with the SS-80–3NC

Getting started is simple. This section will guide you through the initial setup, from installation to operation, ensuring you can hit the ground running.

Future Developments and Updates

Stay ahead of the curve with updates on the latest enhancements and future technology integrations planned for the SS-80–3NC, keeping your operations at the cutting edge.

Conclusion

The SS-80–3NC CNC Automatic Busbar Machine represents a significant leap forward in manufacturing technology, combining versatility, efficiency, and precision in one machine. For businesses looking to scale their production without compromising quality, the SS-80–3NC is an essential investment. With this bus bar bending cutting punching machine, you’re not just buying a tool; you’re setting a new standard in your industry

Comments

Please login above to comment.